Titanium in Defence and Protection

Titanium offers exceptionally high strength in relation to its low weight, making it ideal for the construction of military vehicles, armor, weapon systems and aircraft. With its low weight, vehicles and aircraft can be more efficient and agile while still being strong enough to withstand high stresses.

Moreover, titanium and its alloys have excellent heat resistance, making them suitable for use in aircraft turbines, jet engines, weapons and rockets, all of which are exposed to extreme temperatures. This property helps maintain the structural integrity of military equipment under high-temperature conditions.

Titanium is used in the armor of vehicles, tanks, and helmets, as it offers excellent resistance to projectile impacts and explosions. It is lighter than steel, but strong enough to resist ballistic and explosive hits, making it a preferred material for personal protective equipment and vehicle-based armor.

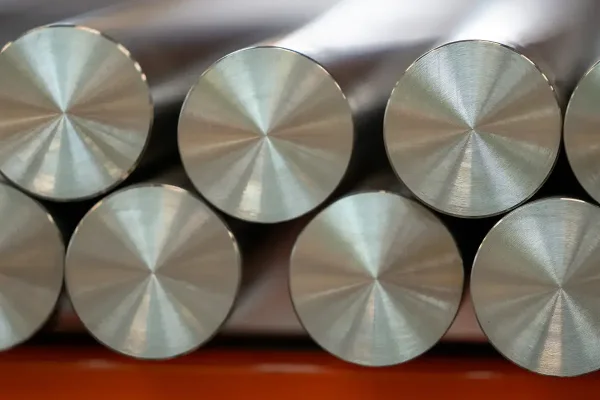

Titanium Semi-Finished Products for Defence and Protection

On over 3000 m² of storage space, ATI offers an extensive range of titanium semi-finished products for the defence and protection sector. These include sheets, plates, bars, welding wires and other specialized materials suitable for the production of military vehicles, protective armor and defence systems. We carry a variety of titanium alloys that meet the specific requirements of this demanding sector. With our service center and comprehensive partner network, we can quickly produce cut parts and custom-made components according to your specifications.

Materials

Titanium Grade 1

Titanium Grade 2

Titanium Grade 3

Titanium Grade 4

Titanium Grade 5

Titanium Grade 5 ELI

Titanium Grade 7

Titanium Grade 9

Titanium Grade 11

Titanium Grade 12

Zirconium

Additional Materials

Semi-finished Products

Sheets

Plates

Bars

Tubes/Pipes

Strips/Coils

Forgings

Other Semi-finished Products