Service Center for Water Jet Cuttings

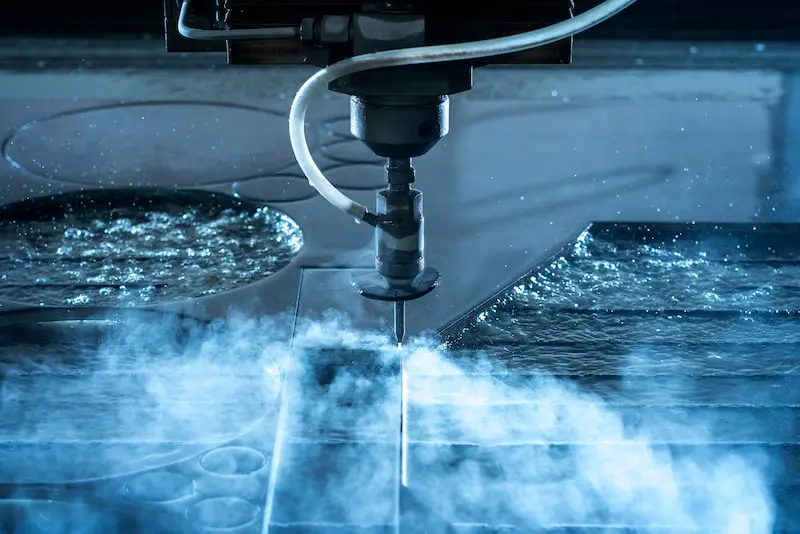

Our service center for water jet cuttings offers tailored solutions for your projects, whether they involve prototypes, small series or large series. Using state-of-the-art OMAX water jet cutting machines, we ensure that your components are cut precisely and efficiently.

Thanks to the high flexibility of water jet cutting, we can achieve complex shapes and tight tolerances without altering the material properties. The water-based cutting process ensures clean cutting edges and minimal material loss, maximizing both cutting quality and cost efficiency.

Our experienced team supports you from consultation and material selection to production, ensuring that your requirements are implemented optimally. Trust in our expertise and cutting-edge technology to efficiently and precisely realize your projects.

Advantages of Water Jet Cutting Technology

Water jet cutting offers many advantages over other cutting methods:

- No thurmal Changes

- No Maechanical Changes

- No Blur Formation

- High Cutting Accuracy

- High utting Quality

- Processing Format: 2,000 x 6,000 millimeters

- Max. Workpiece Weight: 3,000 kilograms

- Operating Pressure: 3,800 bar

- Water Capacity: 16,000 liters

- Material Thickness: up to 200 millimeters

- Machine Accuracy: up to 0.05 millimeters

As an experienced stockist supplier and service center for semi-finished products, we have been supplying small, medium-sized, and large companies around the world since 1998. We are happy to advise you and support you in the procurement and processing of non-ferrous metals. Do you have any questions or would you like to learn more about our services? Our competent employees are happy to assist you and provide consultation. We look forward to your inquiry!