Titan in Hydrogen Technology

Titanium plays a crucial role in hydrogen technology, particularly in the manufacture of electrolyzers used for hydrogen production through water electrolysis. Titanium is extremely resistant to corrosion in acidic and alkaline environments that occur during the electrolysis process, especially when water is split into hydrogen and oxygen. This outstanding corrosion resistance ensures a long lifespan and efficient functionality of the bipolar plates, which are an important component of electrolyzer cells.

Another advantage of titanium in hydrogen technology is its sufficient electrical conductivity, which allows the current to flow through the bipolar plates – a critical factor in the electrolysis process where electricity is passed through water to split it into hydrogen and oxygen. In combination with special coatings, the electrical conductivity of titanium can be further enhanced, thereby increasing the overall performance of the electrolyzer.

A significant advantage of titanium is the ability to coat it with catalysts such as platinum, iridium or ruthenium. These catalysts increase the efficiency of hydrogen production by significantly improving the electrochemical properties of the electrode plates and reducing resistance during the electrolysis process. These coatings optimize reaction speed and contribute to a higher hydrogen yield.

Additionally, titanium offers excellent mechanical strength and structural integrity, even under the high-pressure and high-temperature conditions that can occur in modern electrolyzers. These properties ensure that titanium reliably withstands the mechanical stresses during operation without losing its functionality or stability.

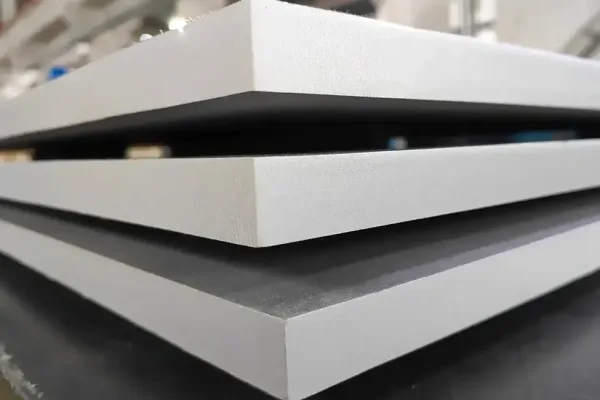

HWN Titan offers customized bipolar plates made from titanium that are manufactured according to the specific requirements and needs of our customers. The surface quality and cleanliness are critical for downstream coating processes and the longevity of the electrolyzer. With our precise manufacturing, we can deliver titanium components that are perfectly tailored to the individual needs of hydrogen production, thus making a significant contribution to optimizing electrolysis processes and the development of sustainable hydrogen technology.

Titanium Semi-Finished Products for Hydrogen Technology

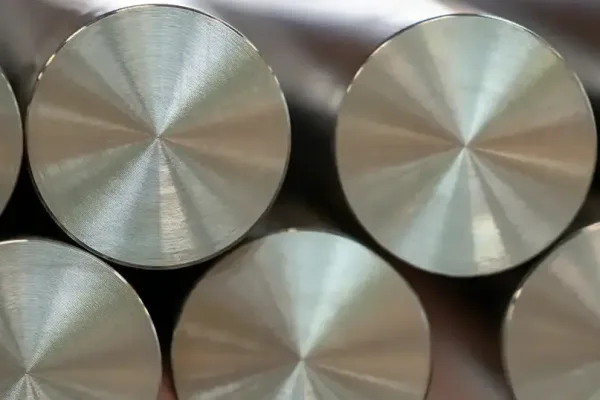

ATI stocks a variety of titanium semi-finished products such as sheets, plates, bars and tubes on over 3000 m² of storage space. Additionally, with our service center and comprehensive partner network, we are capable of quickly producing cut parts of any kind and components made to drawing. Need titanium finished parts? We are the right partner for you.

Materials

Titanium Grade 1

Titanium Grade 2

Titanium Grade 3

Titanium Grade 4

Titanium Grade 5

Titanium Grade 5 ELI

Titanium Grade 7

Titanium Grade 9

Titanium Grade 11

Titanium Grade 12

Zirconium

Additional Materials

Semi-finished Products

Sheets

Plates

Bars

Tubes/Pipes

Strips/Coils

Forgings

Other Semi-finished Products